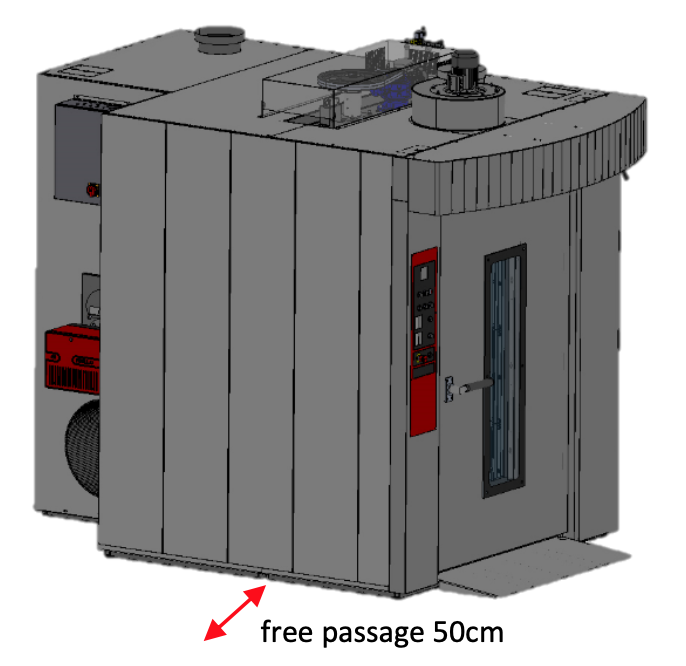

Back burner - Double rack oven

The CR ROTOR series is designed and built to produce any type of bread and pastry product. The oven is reliable, built with quality materials to last over time. The rear burner allows you to save space in width and to have a compact and robust oven. It is suitable for craftsmen and semi-industrial laboratories ensuring maximum versatility and allowing impeccable cooking both at full and half load.

PRE-ASSEMBLED STRUCTURE

- sturdy and fully welded structure;

- The oven is supplied in 2 or 3 semi-assembled pieces (depends on the model).

- Advantages:

- Maximum resistance over time;

- Absence of leaks;

- Easy and quick assembly on site;

-

Ability to pass through any standard 100cm door.

MAIN FEATURE: BACK BURNER

COOKING UNIFORMITY

- The oven has an air circuit designed to wrap the trolley during rotation;

- Cooking is perfectly homogeneous on each tray of the trolley, in all its parts;

- The air flow is directed by adjustable shutters;

- The specially designed lateral cavity alows the correct air flow.

MAINTENANCE AND EASY ACCESSIBILITY

- A lateral space must be provided for the maintenance of the rear boiler.

- The burner is installed at the rear;

- The glass can be removed for easier cleaning;

- The steamer is installed inside the chamber for al its height.

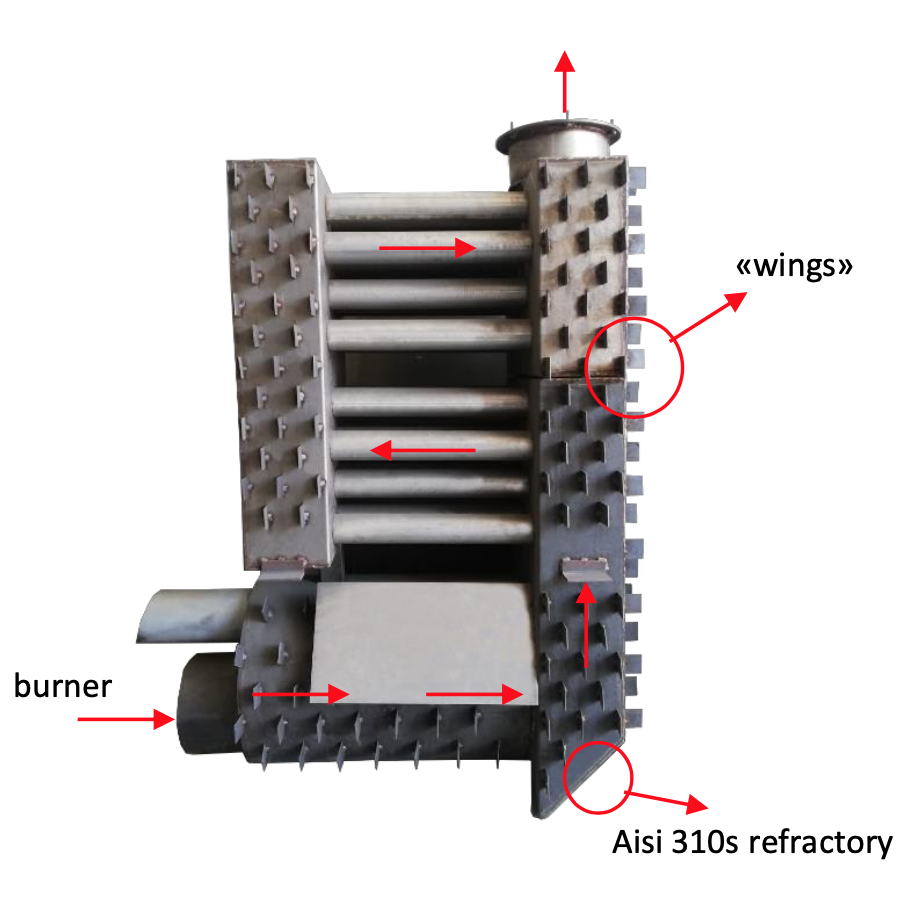

HEAT EXCHANGER

- The heat exchanger is made of special thick refractory steel, resistant to high temperatures and equipped with special “wings” for slow transmission and retention of heat;

- Its «DIRECT» structure allows the quick passage of heat through the pipes, even at maximum power, at high temperatures and for very long periods of time;

- The high number and size of the circular section tubes of which it is composed allows excellent performance.

The fan pushes the hot air up to the steamer and sucks in the hot air coming from the combustion chamber.

STEAMER

- The powerful steamer positioned inside the chamber covers the entire wall for its entire height and guarantees abundant steam production even in the presence of a continuous work cycle, rapid recovery times and homogeneous steam distribution throughout the trolley;

- The steamer is made up of a very strong pocket column and allows the insertion of both standard rods and the famous cast iron spheres;

Optional: Steamer with spheres or with mixed structure “spheres + iron bars”.

THE DOOR

- High thickness (data sheet)

- Satin stainless steel

- Double glass

- Adjustable rotation pin

POWER SUPPLY

In CR ovens the burner is located on the back.

The power supply can be:

- Diesel, methane or LPG burner (1)

- Armored heaters (2)

- Pellet system

(1)

(2)

ELECTROMECHANICAL

TOUCH SCREEN

Allows:

- Inverter

- Air adjustments (10 speeds)

- 100% recipe storage and data analysis

HOOK

Rotor CR ovens have different types of hooking:

- Classic hook (1)

- Platform (2)

(1)