Front burner

The ROTOR INDUSTRIA model was born from the decades of experience of our technicians, designed and built to produce any type of bread and pastry product.

The Industria rotary oven is a reliable oven, built with quality materials and selected electronics, a guarantee of a profitable investment over time. It is suitable for craftsmen and semi-industrial laboratories, it guarantees maximum versatility and allows impeccable cooking with full or half-empty trolley.

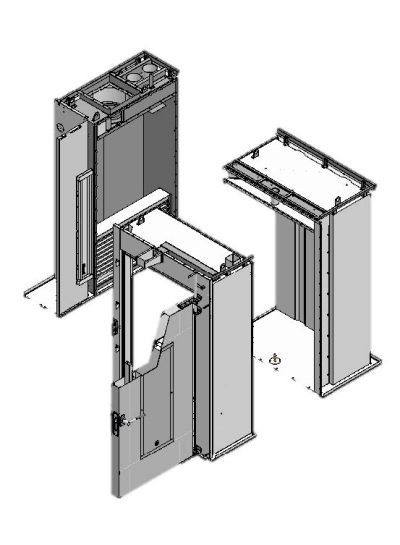

PRE-ASSEMBLED STRUCTURE

- sturdy and fully welded structure;

- The oven is supplied in 2 or 3 semi-assembled pieces (depends on the model).

- Advantages:

- Maximum resistance over time;

- Absence of leaks;

- Easy and quick assembly on site;

- Possibility to pass through any standard 100 cm door.

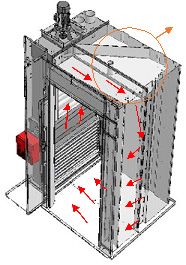

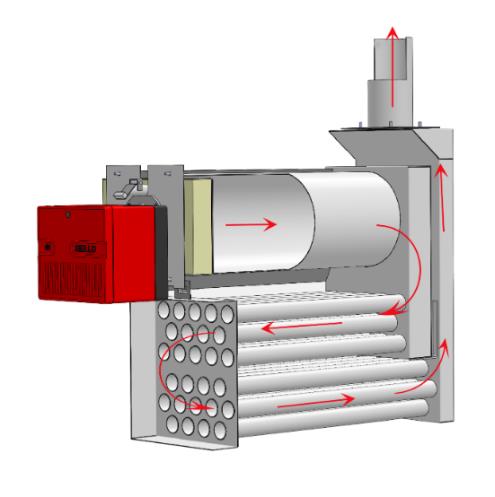

COOKING UNIFORMITY AND PERFECT AIR CIRCULATION

• The oven has the best possible air flow, from bottom to top, to reproduce the refined ground effect, typical of deck ovens, even on the rotary oven;

• The cooking is perfectly homogeneous for each tray of the trolley and in all its parts;

• The double ascending air flow (front and rear) is regulated by shutters;

Upper cavity for a perfect air flow, from bottom to top

MAINTENANCE AND EASY ACCESSIBILITY

- Easy access to all parts needing maintenance

- The burner is positioned frontally, inside a dedicated door;

- Boiler and steamer can be fully inspected thanks to the easy removal of the steel protection, directly inside the chamber;

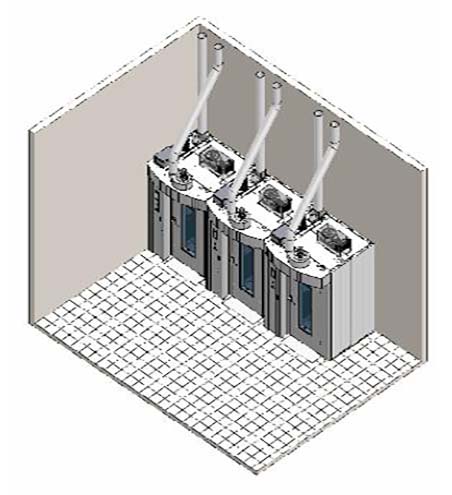

- The Rotor Industria oven is the perfect oven for installations between 3 walls or in series with other ovens without having to lose useful working spaces.

INNOVATIVE HEAT GENERATION WITH LOW CONSUMPTION

- The heat exchanger is made of aisi 310s special refractory steel of great thickness, resistant to high temperatures.

- High number and size of circular section tubes allow excellent performance

- Its “INVERSE” and INNOVATIVE structure allows the heat to be retained inside for a longer period than any other oven, causing the burner to ignite much less frequently and this leads to considerable energy savings;

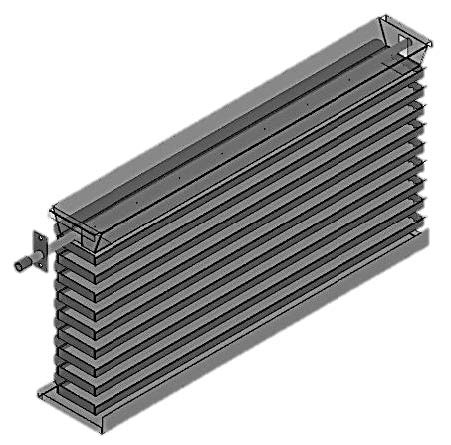

Optional: TRADITIONAL heat exchanger, with “draft” flue gas outlet

STEAMER: homogeneous humidity every time you need it.

- The humidity introduction into the chamber in the first minutes of the baking process of leavened products allows the development of the structure and the browning of the external surface of the product.

- The powerful steamer positioned close to the heat exchanger guarantees abundant steam production even in the presence of a continuous work cycle, rapid recovery times and homogeneous distribution over the entire trolley.

- The steamer is made up of an expansion tank and 9 modular elements, easy to access, with removable sections to facilitate maintenance.

Optional: Steamer with spheres or with mixed structure “spheres + iron bars”.

THE DOOR

- High thickness (data sheet)

- Satin stainless steel

- Double glass

- Internal cavity to avoid overheating

- Steel handle

- Adjustable door

- Movement on self-lubricating brass bushings

POWER SUPPLY

In INDUSTRIA ovens the burner is located in the front, an optimal solution for functionality, maintenance and heat output.

The power supply can be:

- Diesel, methane or LPG burner (1)

- Armored heaters (2)

- Pellet system

(1)

(2)

CONTROL PANEL

ELECTROMECHANICAL

TOUCH SCREEN

Allows:

- Inverter

- Air adjustments (10 speeds)

- 100% recipe storage and data analysis

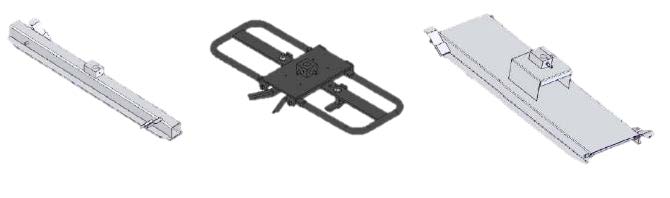

HOOK

- Rotor INDUSTRIA ovens have different types of hooking:

- Classic hook (1)

- Platform (2)

- Automatic lifting (3)

- Special / bespoke if needed (4)

(1)

(2)