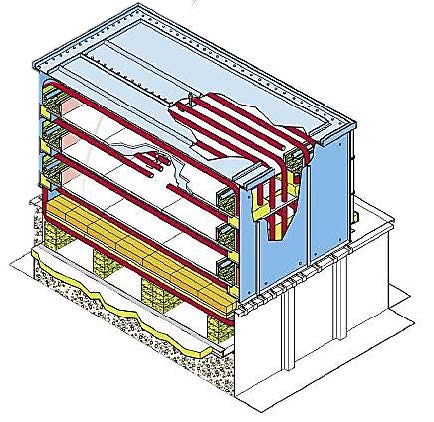

The VAPOR series of deck ovens is designed and built to produce any type of bread, especially large bread. The oven is extremely reliable, built with quality materials and designed as the best ovens of the past, to ensure the perfect combination of traditional cooking and innovative research of materials. It is suitable for artisans and semi-industrial laboratories, it guarantees maximum versatility with impeccable cooking of both fresh and frozen items, both at full and half load.

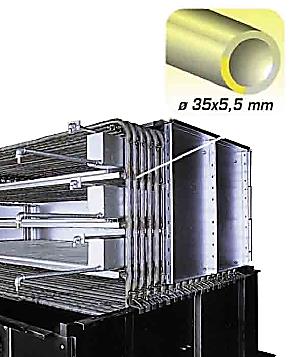

MAIN FEATURE: ANULAR TUBES DIAM. 35mm, THICKNESS 5.5mm

RING TUBES and QUALITY CONTROL

- The annular tubes are in Fe, diameter 35mm (or 27mm as optional), thickness 5.5mm.

- Each tube is manually and welded to guarantee a perfect seal over time.

- The tightness of the pipe is tested by a special machine up to 600 atmospheres.

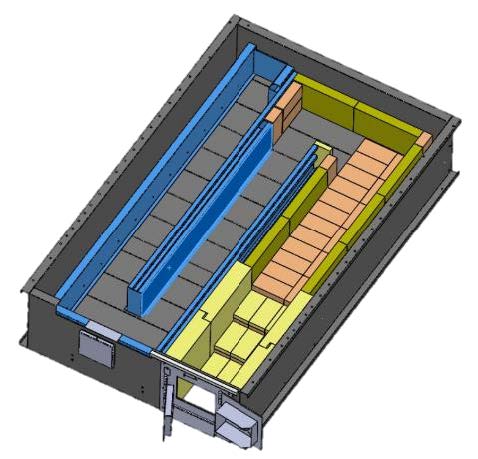

BASEMENT

- The base of a VAPOR oven is the supporting base of the structure.

- We use thick iron, combined with sturdy and continuous welding, to guarantee maximum duration.

- The channels for the flue gas passage are entirely covered with refractory bricks made according to our exclusive recipe.

- The base is designed to be extremely easy to assemble, to save as much time as possible during assembly.

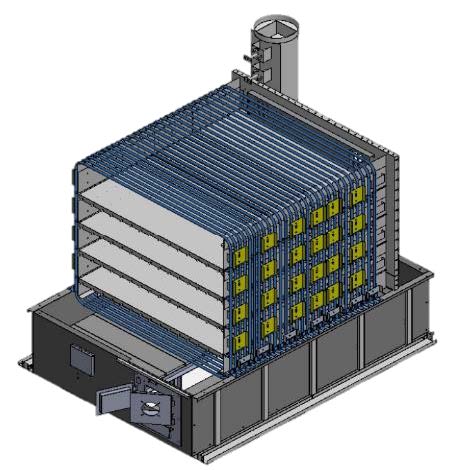

DECKS AND COOKING

- Each tube is placed at a specific distance from each other, to ensure perfect cooking.

- The resulting step comes from years of study and experience and is the secret of the entire structure.

- On each level outlined by the pipes, specific refractory bricks are placed to transfer the heat directly to the dough.

- The maximum recommended cooking temperature is about 300°C. Over this threshold, the safety thermostat will stop the system.

- The oven increases its temperature by about 5°C every minute and in the morning, from cold starting, it takes about 50 minutes to reach the desired temperature.

Our BRICKS are made with a specific and exclusive recipe, the result of years of experience, to ensure maximum heat retention with minimum dissipated energy. The advantage of this choice can be found in the reduction in consumption during the cooking cycle and in the constant color uniformity of the obtained bread.

STEAM

- Each chamber is equipped with 2 internal steel steamers (right and left).

- They are completely independent and guarantee a high and constant steam production;

- Each steamer is easily removable for easy maintenance when and if necessary;

- The amount of steam produced by the steam generators is related to the temperature used in the oven. If an average temperature of about 240 ° C is used, steam can be obtained for about 5 continuous seconds.

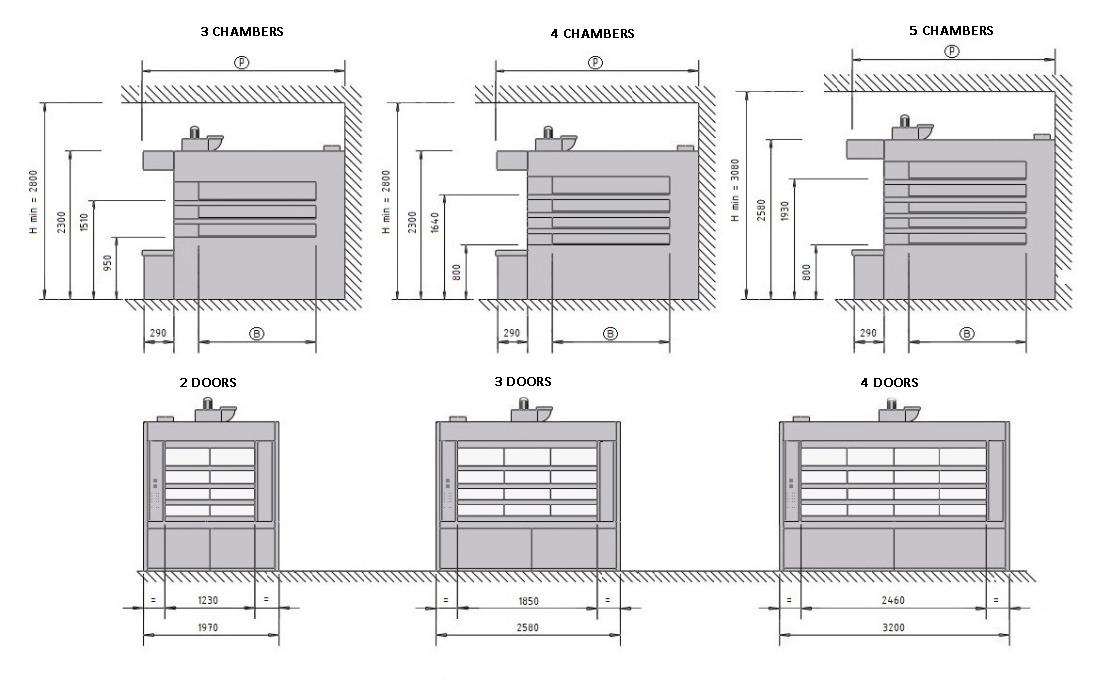

GLASSES AND DOORS

Each oven can be customized with the number, type and size of doors.

- Available sizes: 615mm 750mm;

- Available materials:

- glass with double chamber 20mm

- Aisi 430 steel

- The opening can be upwards or downwards, depending on the model chosen.

- Each door is perfectly balanced.

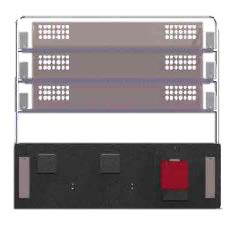

CONTROL PANEL:

- Standard electromechanical

- Touch screen on request

Power 24V

POWER SUPPLY

- Gas / oil burner

- Wood

- Pellets

OPTIONAL: FURNACE FOR WOOD